Professional Experience

Rocket Lab

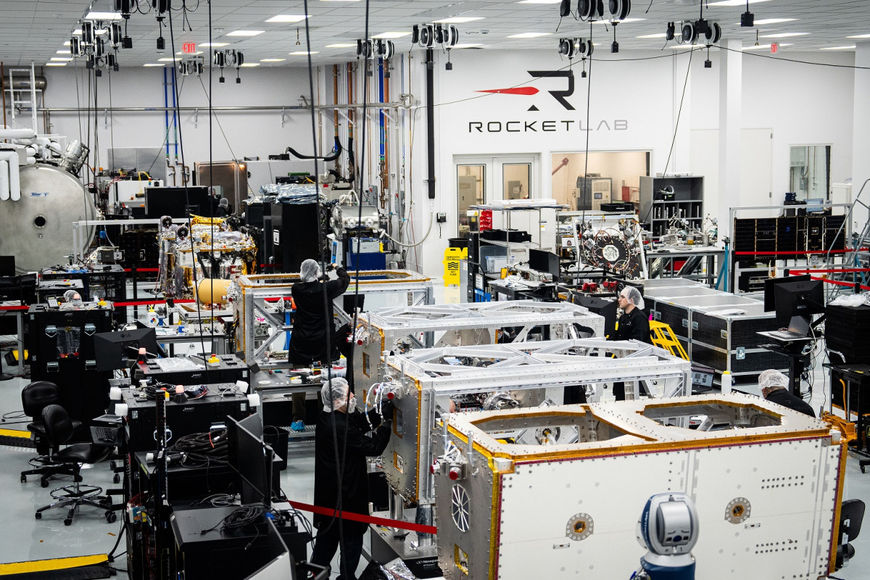

Integration and Test Intern

I worked on the Integration and Test team at Rocket Lab for the Fall 2025 term. I worked on the LOXSAT, Victus Haze, Scorpius, Echo, and Thunder satellite programs. This includes Lightning and Photon bus platforms. My role involved commanding the spacecraft, troubleshooting subsystems, working on flight hardware testing components, and running TVAC campaigns. This included testing reaction wheels, RCS systems, torque rods, fine sun sensors, batteries, IMUs, magnetometers, cameras, solar arrays, and onboard computers.

Testing included safe to mates, bonding measurements, AFTs, lamp testing, quality inspections, and many others. I have also designed and fabricated electrical harnesses for flight components for LOXSAT and Scorpius batteries. I designed and constructed a flight battery charging rack with remote usage for all future satellite testing. I have written and completed procedures on Echo and LOXSAT solar arrays. I designed mylar stencils for carbon fiber on the LOXSAT kick stage. I modified, fixed, and operated a unit test and a large TVAC chamber. This included writing procedures, fixing insulation, designing a door mount, swapping and installing thermocouples, designing and building TC harnessing for seamless contacts from heaters, designing the LOXSAT TVAC campaign SAS harness, and making protection for solenoids and relief valves.

My responsibilities have included performing MTF measurements and vibration testing on Victus Haze payload cameras, as well as maintaining compliance through cleanroom, CUI, and US export control.

This experience has deepened my understanding of system-level integration, testing protocols, satellite systems, fluid systems, electrical systems, controlled testing, and hardware reliability.

NASA, Embry-Riddle

Research Assistant

I worked as a NASA Summer Intern under the Composites Laboratory at Embry-Riddle. I researched synthetic and natural fiber composites, testing modulus, hardness, and other material properties.

I shadowed PHD students and supported their projects. This included designing a 3D resin printed nozzle for jute natural fibers, forming crystals on etched carbon fiber and natural fibers, operating an autoclave for curing the composites, working with acids and flammables, operating a nanoindentor, performing single fiber scratch and nanoindentation experiments, and developing hydrothermal experiments.

I was assigned a carbon fiber curing project. The goal was to create a method to measure the modulus of carbon fiber prepreg as it is curing. The idea I came up with was to use the nanoindentor's thermal fixture and mechanically control the pressure to simulate an autoclave experience on the fibers. I designed and machined a tool to induce pressure on the sample, less than 10 mm large. I tested initial samples, and I am currently working on more consistent mounting and probing methods for the experiment.

I used and completed tasks on a nanoindenter, atomic force microscope, electron microscope, optical microscope, autoclave, composite 3D printer, metal 3D printer, fume hood, ultrasonic mixer, polishing machine, and others.

Executive Air GRB

Mechanical Intern, Aircraft Mechanic

I worked on piston, jet, and turboprop aircraft, performing complex tasks and maintenance. This involves avionic systems, control surfaces, instrumentation, powerplants, structure, and safety equipment.

I performed inspections on aircraft with complete internal engine overhauls, explosive parachute testing, APU and landing gear hydraulic chemical testing, wiring harness tests, oil and fluid changes, and wheel bearing testing. I built and changed landing gear assemblies, following diagrams and troubleshooting wear. Maintenence also included resoldering attitude components, fixing and installing full interiors, aircraft taxing and operation, and more.

I upheld FAA safety standards throughout the process. This internship greatly improved my mechanical ability with tooling, documentation, and engine systems.

Other

01

Buisiness Owner and Founder

I started my own business, sealing and repairing asphalt driveways and parking lots in the Green Bay area. I obtained consistent high-level customer satisfaction feedback. I acquired mechanical problem-solving skills working on Honda engines and sealant pump systems. I ordered all the necessary materials for each projects.

02

Bartender

I worked as a bartender at Lodge Kohler in Green Bay, Wisconsin. I created and maintained a detailed bartending menu for a fine dining restaurant. I worked with produce and other perishables, changing the menu to minimize food waste.