Projects

MOE Ground Support Equipment

Fluid System Project

I am the Ground Support Equipment Responsible Engineer for our MOE bipropellant liquid rocket project. MOE is a rocket attempting to break the collegiate altitude record at FAR in California. This rocket needs to be stacked, fueled, and pressed in two hours. This is where my system comes in.

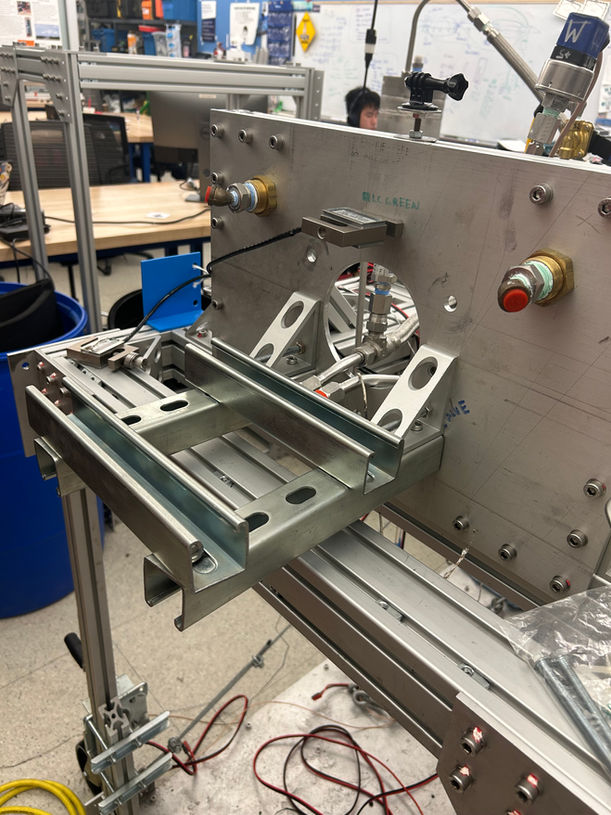

I designed a complete ground fueling system capable of handling liquid oxygen at 500 psi, isopropyl alcohol at 300 psi, and gaseous nitrogen at 6000 psi. It has multiple fail-safe modes ensuring the test team will be safe during operation.

My work included specifying and sizing pneumatic ball valves, solenoids, and relief valves to ensure reliable, fail-safe operation under demanding conditions. This culminated in a three-line system for each fluid.

Another requirement was to design a way to actively disconnect safely from the rocket before launch. I also designed a custom pneumatic quick-disconnect mechanism to enable safe system separation during fueling. This releases the fueling hoses from the GN2 and LOX lines right before launch with pneumatics that separate open flow disconnects from the rocket.

Beyond design, I did trade studies and system integration reviews while creating detailed CAD models, P&IDs, and component diagrams. I modeled the system to have a safety factor of 2.0. I managed sourcing and fabrication and led technical design reviews. We are currently building this system and will begin full integrated testing in the spring. This project strengthened my skills in fluid systems design, pressure analysis, safety engineering, and hands-on testing, while deepening my understanding of how disciplined hardware design supports reliable rocket operations.

Saguaro Engine Lead

Fluid and Propulsion System Project

I am the lead for a composite rocket engine at the Experimental Rocket Propulsion Lab. I started and ran an engine project named Saguaro, which was a 750lb kerosene and liquid oxygen engine with an integrated torch ignitor. I set weekly meetings, organized team members, set goals, ran PDR presentations, and performed many other responsibilities. Apart from the lead, I designed the coaxial swirl injector and three ignition methods, including a torch, decomposition, and pyrograin.

Our external torch was blown out on our first test before transferring enough energy into our combustion chamber. During the second test, the retraction mechanism failed to fire, which caused the rocket engine's flame to revert back on the test stand and damage the feed system. I took this issue and designed an integrated internal torch. I performed a detailed evaluation of potential ignition approaches, analyzing ignition delay, combustion stability, and hardware complexity and cost. I landed on designing for exit flame temperature in my chamber calculations to be above the auto ignition temperature of a kerosene and liquid oxygen mixture.

This torch feeds off our oxidizer and fuel tanks and fires a flame through an integrated torch tube through a coaxial swirl injector that I designed with a team member to consistently ignite our engines. I redesigned the propellant feed system to ensure compatibility and tuned the ignition sequence for consistent and repeatable engine startups. I completed stress analysis, bolt analysis, and thermal analysis.

Apart from the main torch igniter, I designed two experimental versions. A catalytic decomposition ignitor with nitrous oxide and fly ash to use the autoignition temperature of oxygen and kerosene. The second is a reloadable pyrograin as a redundant option.

Automated Blind Cane

Electrical and Integration Project

Two business majors and I developed a product for a disability competition at the University of Utah. The goal of the competition was to create new technology for the disabled community. Our team came up with an automated blind cane that can guide a user around inaccessible areas in their life. I was tasked with creating a functional prototype that my other two team members are able to market in their future competitions.

I created a guiding system using object recognition cameras and an omnidirectional wheel. I coded a Raspberry Pi with a library of over five thousand common objects one may see in their life, ranging from people to fire hydrants. When the system was over 70% positive of a concerning object, it would trigger a wheel at the base of the cane and move in the opposite direction. I created modifications to common blind canes for mounting hardware for batteries, cameras, and a new base for the wheel and motors.

Once functional, I presented the project to a committee of professors and advisors on the product I created and what community it serves. My team members presented their own boards, and we were scored as a group. Our team won the symposium.

Feed System

Fluid Project

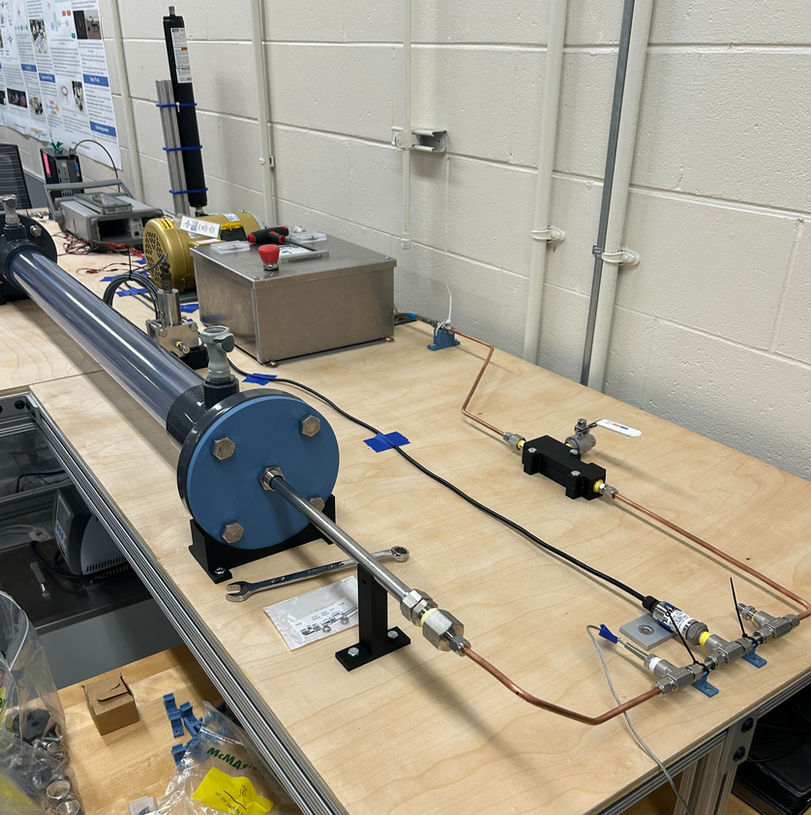

At the rocket club, previous members designed a feed system for engine testing. This system works but needs constant improvement, modification, and more development for future tests.

I have worked with our complex fluid system by addressing FOD issues and safety issues. This includes adding filters inline with our GN2 tanks into the fill tanks, mounting for LOX vents, and others. I also changed the way we pipe-taped all our future fittings. My other contributions include reassembly and testing of pneumatic ball valves, hotfire procedure creation, P&ID creation, test controlling and responsibility, plumbing assembly, part managing, and many others.

I am also on Red Team, where I monitor, actuate, and complete test operations on hotfire days while the system is pressed. This requires intricate knowledge of the fluid system, where pressure is and is not throughout the feed system while in different states, to ensure safety and efficiency during the test.

Supercritical Flow Loop

Thermal Project

During my time working in the Thermal Science Lab at Embry-Riddle, I was paired with a PHD student. We noticed that carbon dioxide has a large spike in heat flux at a stage in its supercritical state.

We developed a test stand to measure the heat transfer coefficient. This included a corrugated aluminum pipe that would flow high-pressure and high-temperature carbon dioxide through a bath of water. We would measure the temperature change of the water from a calculated mass flow rate over time to determine the coefficient.

I made spot-welded thermocouples, conducted pressure tests, built fluid hardware, bent tubing, and calibrated DAQs.

Other

Prototype Avionics Box

Space Technologies Lab

I designed a prototype for Intuitive Machine's Lunar Lander for an avionics box controlling cameras documenting landing on the moon.

Water Pump Competition

University of Utah

Competed with a team to create the most effective water pump with one spool of 3D printer filament, 4040 aluminum, a drill, and a timer of 24 hours.

Motercycle

Personal

Rebuilt a totalled 1979 Kawasaki KZ 200. Fixed the airbox, carburetor, ignition system, suspension, transmission, and fueling system.

3D Printer

Personal

Designed and built my own 3D printer. Modelled similar to the Prusa MK4. Functions with 1 mm layer heights with PLA.